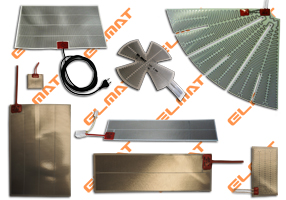

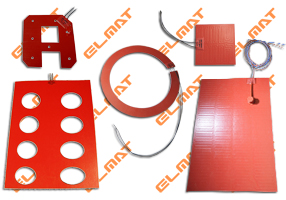

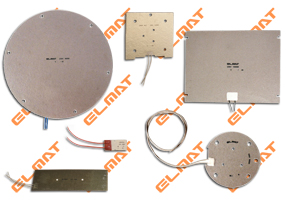

ELMAT® HEATING FOILS

FLEXIBLE HEATERS

General Information:

"ELMAT" heating elements are manufactured by inserting between strata of dielectric insulating material a resistive circuit that can be implemented using different technologies such as metal lamina incision (X-MAT® type), ink or paste deposition (T-MAT02® type) or incorporation of resistive wires (W-MAT02® type)

Consequently, very thin and very flexible elements are produced characterized by significant design possibilities.

Advantages:

- Flexibility and lightness.

- Securing through direct adhesives, hooks, Velcro, vulcanization.

- Differentiation of surface temperature / power.

- Multi-circuit distributions can also be developed.

- Customized geometries.

- Integrated sensors.

- Selection of adhesive supports in relation to temperatures, type of surface and applications.

Technical features of X-MAT® elements

Insulation |

Polyester |

Silicon |

Polyamide |

Mica |

|

Commercial names |

Mylar® |

|

Kapton® |

|

|

Max work temp. |

105 °C |

230 °C |

230 °C |

300 °C |

|

Max temp. with adhesive |

105 °C |

175 °C |

175 °C |

--------- |

|

Max. peak temp. |

130 °C |

250 °C |

250 °C |

375 °C |

|

Typical thicknesses (µm) |

250 |

820 |

220 |

850 |

|

Max. dimensions |

3000 x 600 |

2000 x 600 |

|

Bending radius |

about 8 mm |

about 10 mm |

about 2 mm |

--------- |

Max. load |

6 kg / cm2 |

|

Final testing |

In accordance with EN 60335-1 - MIL 105 standards |

|

Dir. 2002/95/CE (RoHS) |

Completely harmonized with the directive |

Product application methods:

Elements characterized by adhesives on one side require simple operating procedures to ensure correct assembly:

- the surface must be clean and grease-free. Cleaning: use appropriate solvents and de-greasing agents such as heptane and isopropyl alcohol with reference to correct application instructions provided on respective packages.

- Holes, protruding screws and sharp edges must be carefully avoided.

- The surface must be dry prior to application.

- Assembly must be performed at temperatures between 18 and 40°C.

- Avoid application in dusty environments.

- After removing the paper flap protecting the adhesive, the bonding stage may begin by pressing the part already installed with a rubber or wooden roller to eliminate any air bubbles. It is advisable to begin from the part opposite the connection zone and in any case always from the shortest side. Continue sliding out from below the protection paper until the operation is complete.

Do not use the heater immediately after assembly: adhesion of the element improves progressively over the first 48/72 hours after application.

Product storage:

The best conditions for correct storage are:

- environment with temperatures around 20 °C and relative humidity of 40-60%;

- store in the original cardboard box;

- avoid direct exposure to sunlight.

Technical requirements:

- Some materials of the inner laminas are magnetic. Contact our Technical Office for any questions about product specifications.

- The adhesive chosen to secure the resistor is fundamental in ensuring safe use and depends on the application surface. The type of application must be specified in the offer and product definition stages.

- Any thermostats and temperature detection probes must be applied in the zones with the highest temperatures and reduced thermal exchange conditions.

- Increasing the specific load of the resistor requires particular attention as regards temperature control given the low inertia of the X-MAT® heater.

Heater selection criteria:

Correct dimensions and appropriate choice of the functional system requires analysis of the environment where the heating element will be used, identifying the highest number of answers to the following questions:

1) Material to be heated and relative quantitative parameters.

2) Physical-dimensional characteristics of the housing.

3) Type of heating (radiating, convection, conduction, recirculation).

4) For "ELMAT" foil heaters, specify the application methods, type of surface, presence of paint, temperature and relative humidity levels in the event of refrigeration applications.

5) Systems used to secure the heater to the surface (adhesives, vulcanization, mechanical fixing).

6) Presence of external insulation.

7) Thermal level (operating temperature, cold-operation temperatures, any thermal flows).

8) Time needed to reach operating conditions.

9) Electrical parameters available: Volts, Watts, Amperes, Direct or Alternating current, three-phase / single-phase).

10) Dimensions, overall dimensions, critical zones.

11) Ambient conditions (explosive, corrosive areas ….).

12) Approvals required (VDE, UL, CSA, CE ……).

13) Temperature controls: identify the need or otherwise for temperature controls and relative type (bi-metal, potentiometer, electronic, adjustable or fixed, temperature limiters, probes, PT100, thermo-couples and relative types).

|